- #Da vinci aio downgrade firmware pdf

- #Da vinci aio downgrade firmware upgrade

- #Da vinci aio downgrade firmware software

- #Da vinci aio downgrade firmware crack

You can also download this guide as a pdf if you would prefer. Now you have a chance to turn it into something much more versatile.

See the photo below, i added the washer on the right side to adjust for the tension plate washer.Don't be down-hearted. You can either redesign the head block to compensate for the extra. When you add this washer it makes the head block sit crooked. It will probably stick open and you will have all kinds of print problems. That is a needed step as over time the bushing from the tension plate will dig into the head block and cause the tension plate not to move freely. When you start to assemble the carriage you need to put a washer between the filament tension plate and the printed piece that holds the new head. I all goes together just like the video, but I did a little extra. Make sure your up to the task before you grenade your machine. So for the e3d print head in a Davinci here is what I did. I had to do a couple things that the videos didnt cover and I added a couple things to help make a neater install. As with everything I do, it never goes like the videos. Several good videos on line and it wasn't that hard. I went with the e3d V6 and a couple different nozzles. The next logical step well at least in my mind was to ditch the stock print head. And it was free, you cant beat free.Īfter the first upgrade, i was hooked and wanted to do more. I did have a couple issues with loading the firmware, but once I realized what I was doing wrong yes i was wrong, dont tell my wife the process was easy. That alone was an amazing difference in how the printer printed.

#Da vinci aio downgrade firmware software

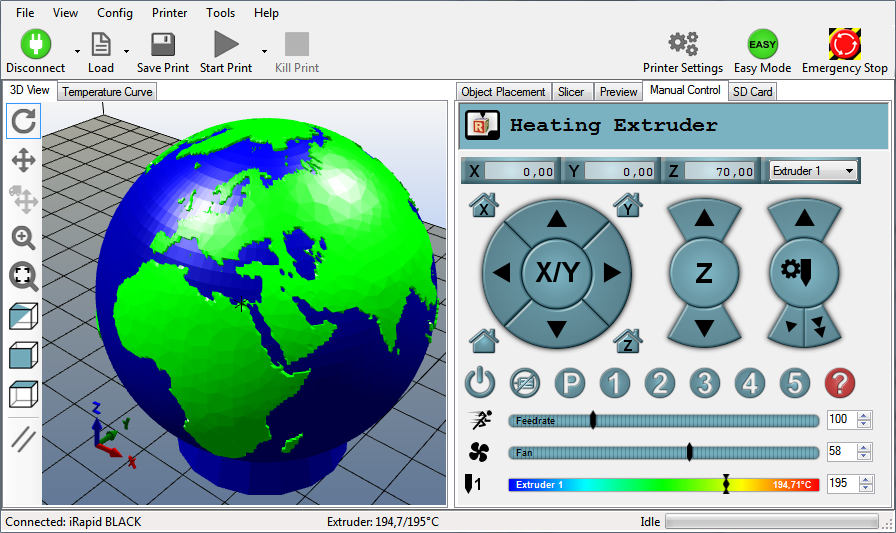

I took the first step and did the Repiter software upgrade.

#Da vinci aio downgrade firmware crack

I really didnt have any issues with the crack in the glass so I just put blue painters tape on the bed and kept printing. I have had my printer for about a year and left it stock.Īs with most Davinci 1. You must login or register to post a reply. Notify me of new posts via email.Active topics Unanswered topics. You are commenting using your Facebook account. You are commenting using your Twitter account. You are commenting using your Google account. Then again it may only be worth salvaging the motors and anything else to build another better printer. I may devote some more time to the DaVinci printer but I think it will take a major overhaul since I have discovered a majority of the mechanics are worn out. The DaVinci just may not be worth spending anymore time on, for the cost of the new nozzle I could have bought half of a second Prusa i3 clone not to mention the time. The quality is not anywhere near my other printer. I am still trying to dial those settings in. Now all that remains is adjusting the software settings in Simplif圓D to produce perfect prints. After removing R29 on the mainboard the temperature reading was within a few degrees of the thermocouple. For some reason the thermistor was not being read correctly. I updated the firmware to use the correct thermistor conversion table and then turned on the printer. Since the thermistor and fan cables are the same color I labeled the wires accordingly, I have a label maker and am not afraid to use it!įuture me will be thankful. Shrink wrap and kapton tape ensure everything stays together. I spliced in the thermistor with the cable provided with the E3D kit and a male header. Using a multimeter I determined that the black and yellow wires on the six pin connector are thermistor inputs. I decided to remove this PCB and connect the thermistor directly to the controller. I added a male connector to be able to adapt these wires to the cable provided in the E3D kit. The connectors on the left of the board expose these pins and I was able to wrap and solder the wires to these points. I attached the E3D 12V fan to the 12V and ground rails directly on the main board. After soldering them to the wires I installed heatshrink to prevent the connectors from shorting to each other or the printer frame. They work great for this since they are rated for high current and best of all cost me nothing extra. I deviated from the wiring instructions in an attempt to provide a cleaner wiring harness and connections. Finally I made a slight modification of Z thickness to provide better clamping force on the E3D v6 since the original reqired sanding before making contact with the hotend mounting shaft. I found a few issues with this adapter during assembly and I modified it to better fit my needs, thing I also adjusted mounting hole dimensions to match those of the NEMA17 extruder motor, the original design may have accounted for shrinkage that I do not see.

#Da vinci aio downgrade firmware upgrade

With my new Tronxy printer I was able to print the mounting hardware to upgrade the hotend on my DaVinci 1.

0 kommentar(er)

0 kommentar(er)